In the design and maintenance of automation control systems, the proximity switch is one of the most frequently used sensors. However, faced with a wide array of models, many novice engineers often get stuck at the first hurdle: Should I choose a PNP or NPN type for my equipment?

They look almost identical externally, but choosing the wrong one can mean the equipment fails to recognize the signal, or worse, damage the optocouplers at the PLC input points. This article will thoroughly explain the difference between PNP and NPN proximity sensors, from principle and wiring to selection.

I. The Core Difference: Output Transistor Logic

PNP and NPN refer to the type of transistor used in the sensor's internal output stage. For the end user, there's no need to delve into semiconductor physics; we just need to understand the different logic states of their output signals.

We usually liken the sensor to a switch that controls the flow of signal current to the PLC.

1. PNP Sensor: Sourcing Output

Layman's Explanation: A PNP sensor, when triggered, "provides" a positive voltage signal.

Working Principle: When the sensor detects a target object and turns ON, its internal PNP transistor conducts, connecting the positive supply voltage (usually +24VDC, Brown wire) to the signal output (Black wire). At this point, the output presents a high level relative to the negative supply (Blue wire).

Keywords: High active, Positive switching, Sourcing current.

2. NPN Sensor: Sinking Output

Layman's Explanation: An NPN sensor, when triggered, "provides" a path to the negative (ground).

Working Principle: When the sensor detects an object and turns ON, its internal NPN transistor conducts, connecting the signal output (Black wire) to the negative supply voltage (0V, Blue wire). At this point, the output acts as a ground connection, presenting a low level.

Keywords: Low active, Negative switching, Sinking current.

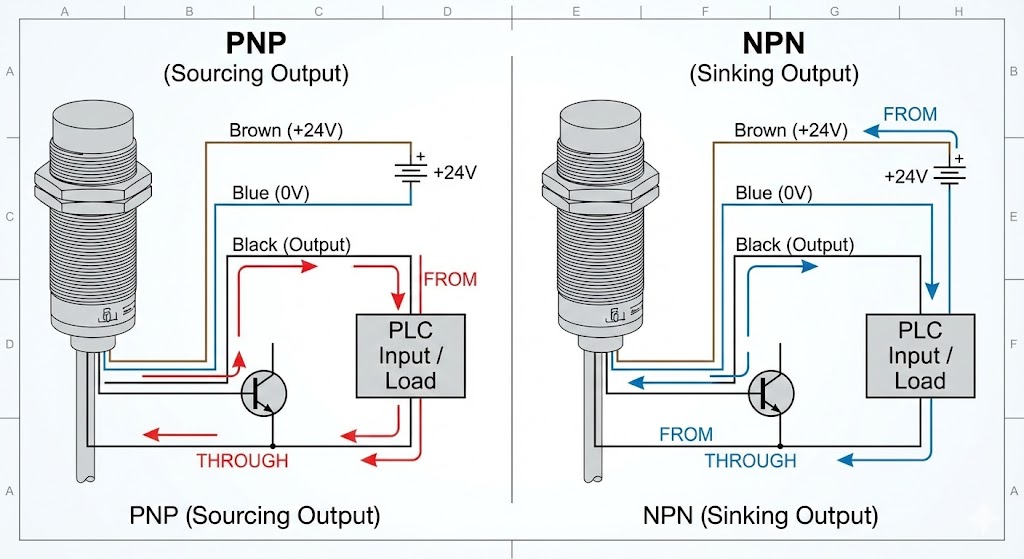

II. Visual Comparison: Differences in Wiring

Once the principle is understood, wiring becomes straightforward. This is where the difference is most directly manifested.

PNP Wiring: One end of the load (such as a PLC input point or relay coil) is connected to the sensor's output wire (Black), and the other end must be connected to the negative power supply (0V, Blue). Current flows out of the sensor, through the load, and back to the negative supply.

NPN Wiring: One end of the load is connected to the positive power supply (+24V, Brown), and the other end is connected to the sensor's output wire (Black). Current flows from the positive supply, through the load, and flows into the sensor, finally going to the negative supply.

III. Selection Guide: How to Decide?

In practical applications, choosing between PNP and NPN usually depends not on the sensor itself, but on the input type of your controller (PLC).

Check the PLC Input Module's Common Terminal (COM):

If the PLC input module's COM terminal is connected to the negative power supply (0V), the PLC needs to receive a high-level signal, and you must choose a PNP type sensor. This is most common in European brand PLCs (like Siemens).

If the PLC input module's COM terminal is connected to the positive power supply (+24V), the PLC needs to receive a low-level signal, and you must choose an NPN type sensor. This is common in Japanese and Taiwanese brand PLCs (like Mitsubishi, Omron).

Regional Preferences:

The European market favors PNP because positive logic is easier to understand and offers slightly higher safety in certain fault conditions (ground shorts won't cause false triggers).

The Asian market (especially Japan) traditionally uses NPN extensively.

The US market uses a mix of both.

Conclusion

Clarifying the difference between PNP (Sourcing, outputs positive voltage) and NPN (Sinking, outputs negative voltage) allows you to navigate complex industrial sites with ease.

As a global electrical industry supply portal, Sense-the-World (